ENJOY 0% FINANCING - BUY NOW PAY LATER

- Browse

- Newest Items

- CLEARANCE DEALS

- Air Intakes

- Brakes

- Body | Aero Parts

- Driveline

- ECU Tuning

- Electronics

- Engine

- Exhaust Parts

- Exterior

- Fuel Components

- Gauges

- Handlebars & Controls

- Interior

- Lighting

- OEM Parts

- Package Deals

- Racing Gear & Apparel

- Suspension

- Turbo | Supercharger

- Tires

- Wheel Accessories

- Wheels by Size

- Wheels by Vehicle

- Tools and Maintenance

- Universal & Repair

- Vivid Racing Gear

- Shop by Vehicle

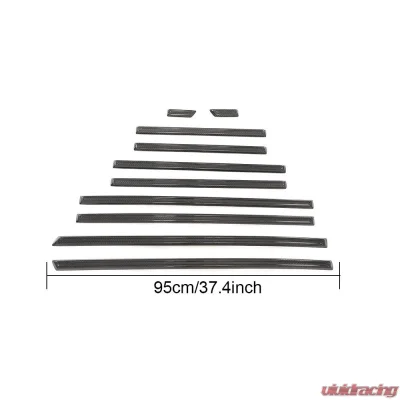

Comp Aero Carbon Fiber Door Molding 10pc Set Mercedes G63 AMG W464 2022-2023

Select the year of your Mercedes-Benz G63 AMG:

Enhance the appearance of your Mercedes G63 AMG W464 2022-2023 with the Comp Aero Carbon Fiber Door Molding 10pc Set. Made with precision CNC machined molds created from 3D scanning of vehicles, these carbon fiber parts are perfectly styled and fitted to give your vehicle a more aggressive and pronounced appearance. Each part is hand laid in the mold using 2x2 carbon fiber pre-preg material and transformed inside an autoclave, resulting in a high gloss UV resistant coating for a perfect OEM finish. Professional installation is recommended for optimal results.

But these carbon fiber parts are not just about looks. They are also designed to provide unparalleled strength-to-weight ratios, making them indispensable in high-performance automotive applications. The use of advanced carbon design technologies, such as automated fiber placement (AFP) and 3D weaving, allows for intricate and tailored layup patterns that enhance performance and durability. The integration of finite element analysis (FEA) and computational fluid dynamics (CFD) further optimizes component efficiency and performance.

Not only are these products top-of-the-line in terms of design and technology, but they are also made to order and take about 4-6 weeks for delivery. Please note that they ship directly from the factory overseas and are subject to Import Duty and Taxes, for which the purchasing customer is responsible for all related costs.

Features and Benefits:

- Enhances the appearance of your Mercedes G63 AMG W464 2022-2023

- Precision CNC machined molds for a perfect fit

- Hand laid 2x2 carbon fiber pre-preg material for strength and durability

- High gloss UV resistant coating for a perfect OEM finish

- Includes high quality double sided tape and hardware for easy installation

Founded in 2013, Comp Aero has a rich legacy spanning over three decades in the carbon automotive design industry. From a small workshop specializing in advanced composite materials, the company quickly established itself as a pioneer in carbon fiber technology. With a relentless commitment to innovation, Comp Aero has evolved into a premier carbon manufacturing and design firm, utilizing cutting-edge techniques such as resin transfer molding (RTM) and prepreg autoclave processing to ensure unparalleled strength-to-weight ratios.

The company's expertise also extends to the use of CNC molds, which enable precise and repeatable production of complex carbon fiber components, ensuring optimal aerodynamics and structural integrity. In addition to traditional methods, Comp Aero has embraced advanced carbon design technologies, including automated fiber placement (AFP) and 3D weaving, to enhance performance and durability. The integration of finite element analysis (FEA) and computational fluid dynamics (CFD) in their design process further optimizes component efficiency and performance.

Comp Aero's dedication to excellence and innovation has cemented its reputation as a leader in the carbon automotive design industry. Their continuous pursuit of perfection ensures they remain at the forefront of carbon fiber technology, delivering state-of-the-art solutions for the automotive sector.

Other Part Numbers:

Comp Aero #ML-LQ118-MY

⚠ WARNING:

Cancer and Reproductive Harm

https://www.P65Warnings.ca.gov

| Make Vehicle | Model | Submodel | Year | Engine | Notes |

|---|---|---|---|---|---|

|

2018-2023 Mercedes-Benz G63 AMG |

G63 AMG | 2018-2023 |

The company prides itself on utilizing cutting-edge techniques in carbon fiber production, such as Resin Transfer Molding (RTM) and Prepreg Autoclave Processing. These methods ensure unparalleled strength-to-weight ratios, making their products indispensable in high-performance automotive applications. Comp Aero's expertise extends to the use of CNC molds, which enable precise, repeatable production of complex carbon fiber components, ensuring optimal aerodynamics and structural integrity.

In addition to traditional methods, Comp Aero has embraced advanced carbon design technologies, including Automated Fiber Placement (AFP) and 3D weaving. These techniques allow for intricate, tailored layup patterns that enhance performance and durability. The integration of Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) in their design process further optimizes component efficiency and performance.

Comp Aero's dedication to excellence and innovation has cemented its reputation as a leader in the carbon automotive design industry. Their continuous pursuit of perfection ensures they remain at the forefront of carbon fiber technology, delivering state-of-the-art solutions for the automotive sector.

Check out these other great products

Help Me Decide

One of our experts would be happy to help you navigate these options and get the exact part you need. We can contact you via phone or email.